Wheel Bearing Retainer

1 x $65.00Brake Conversion Kit

1 x $85.00OE Replica Wheels

1 x $92.00Shock Mount Insulator

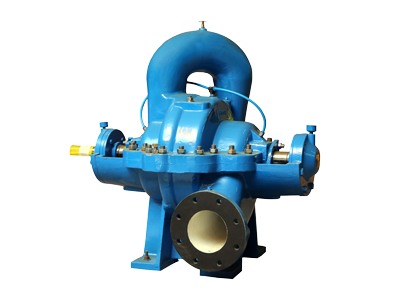

1 x $68.00Industrial Pumps

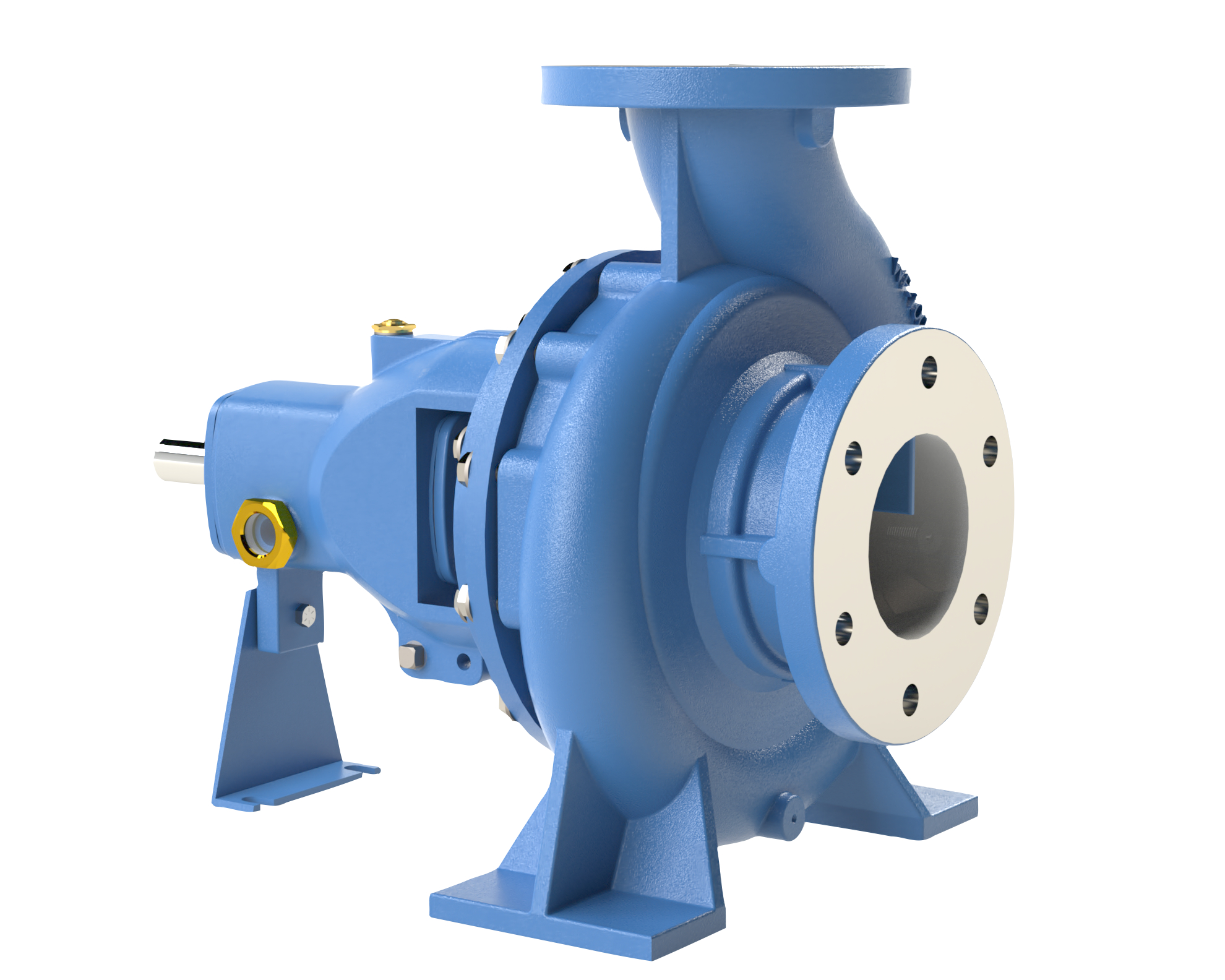

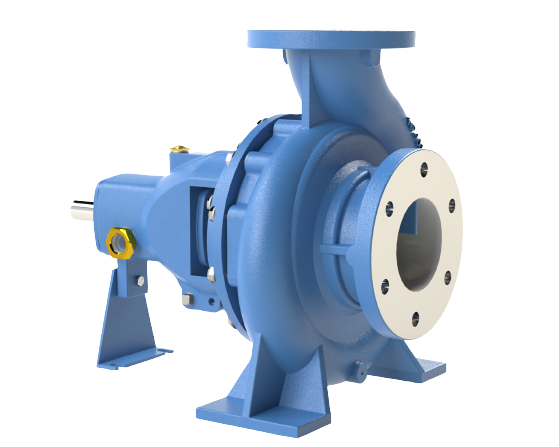

Water Pumps

KEERTHI Pumps is renowned for manufacturing the highest quality Industrial pumping and utilizing the best engineering practices available worldwide. WP series is the single stage end suction pump has been designed with latest CAD (Computer Aided Design) and CFD (Computational Fluid Dynamics) for better energy efficient.

Industrial Pumps

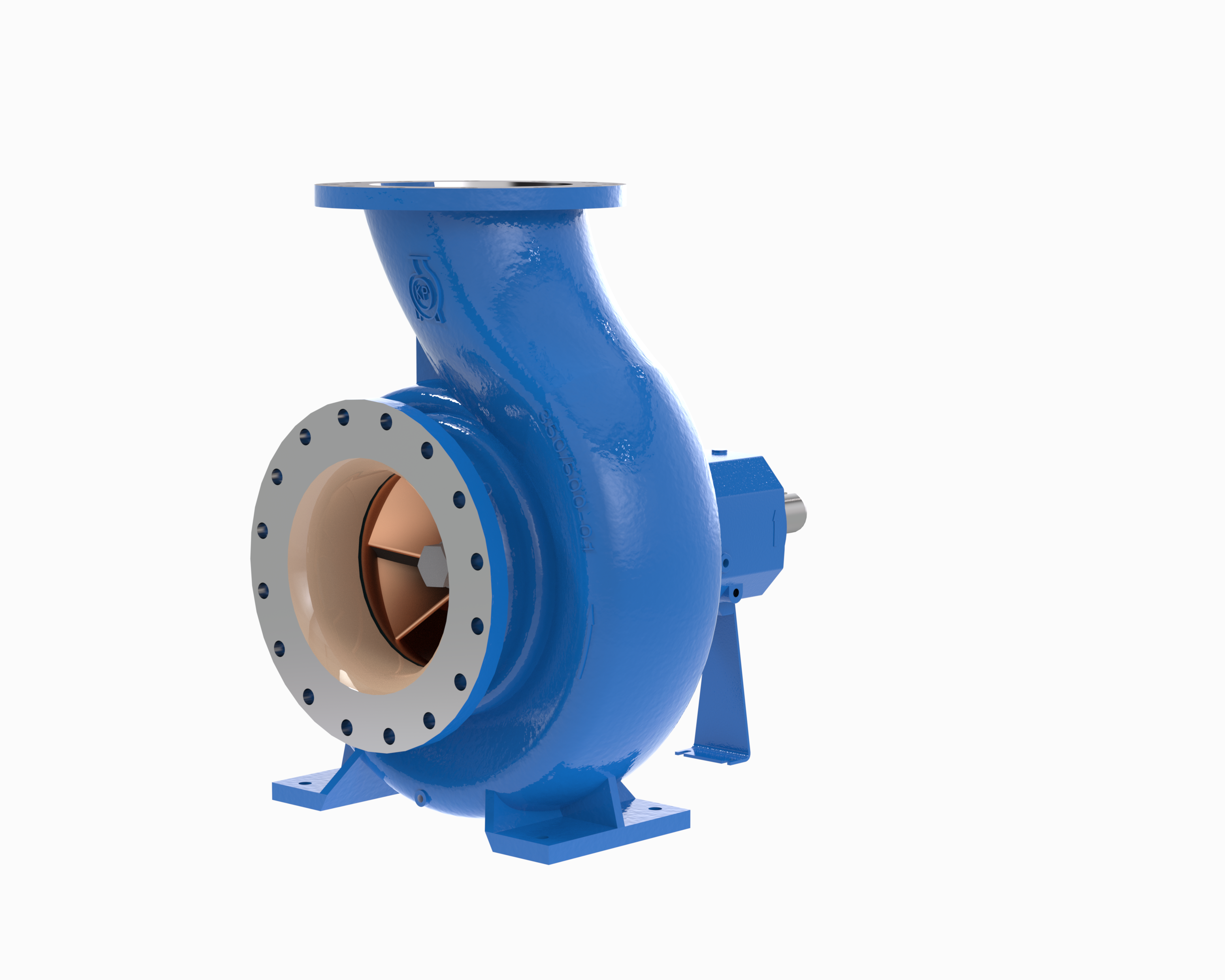

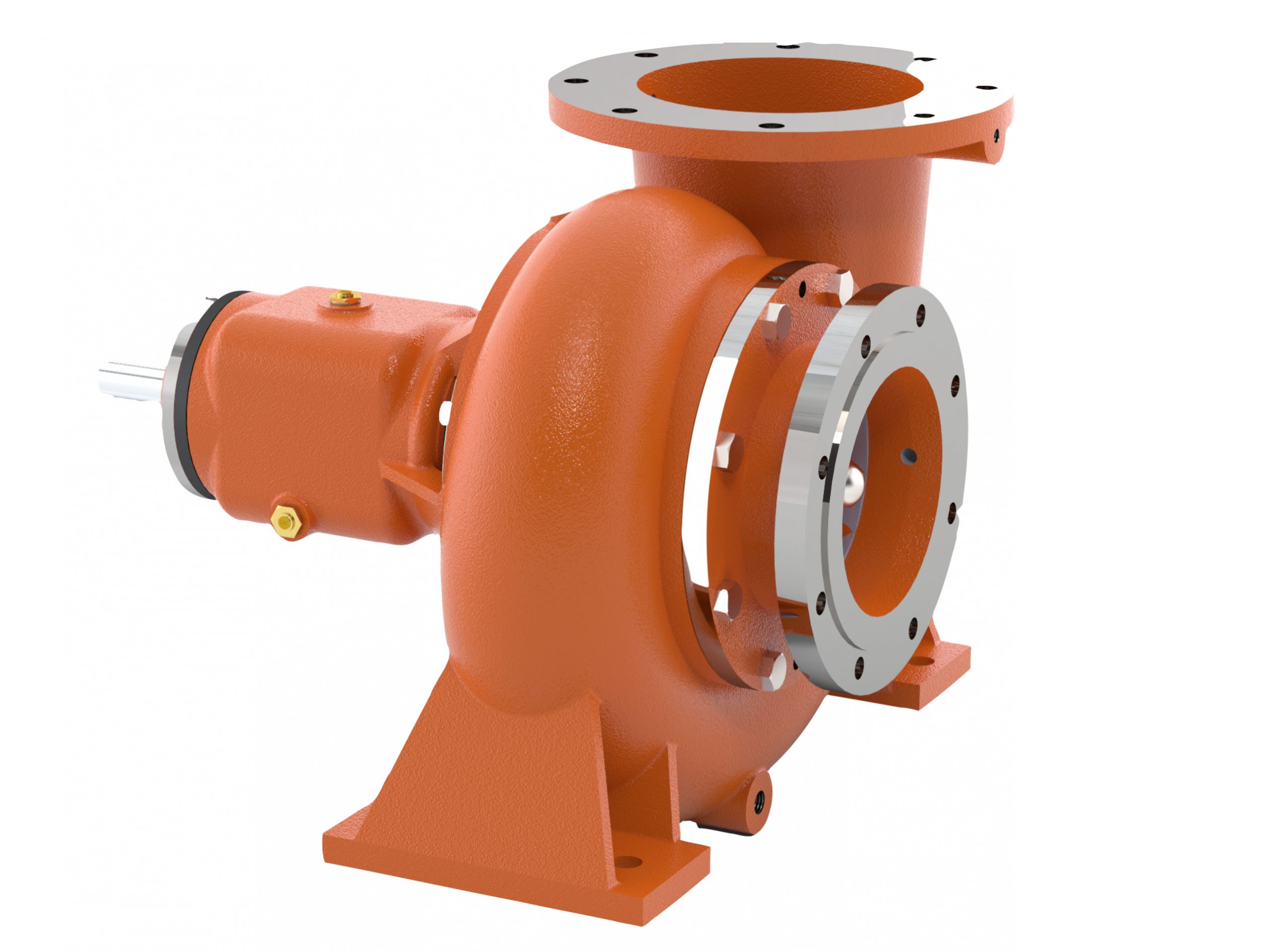

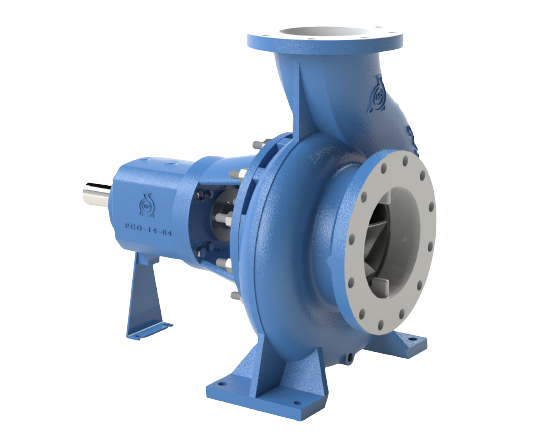

Chemical Process Pumps

KEERTHI Pump has been producing robust, high-efficiency pumps for the Industrial market for two decades and our innovative pumps have provided unmatched value. KEERTHI Pumps – KCP Chemical process pumps series, is specially designed for all pumping Chemical liquid, clear water, solids handling, and grit/slurry pumps provide the reliability and inter-changeability demanded in industrial applications. KEERTHI Pumps offers a wide range of Chemical Process pump models and configurations to fit into existing installations.

Industrial Pumps

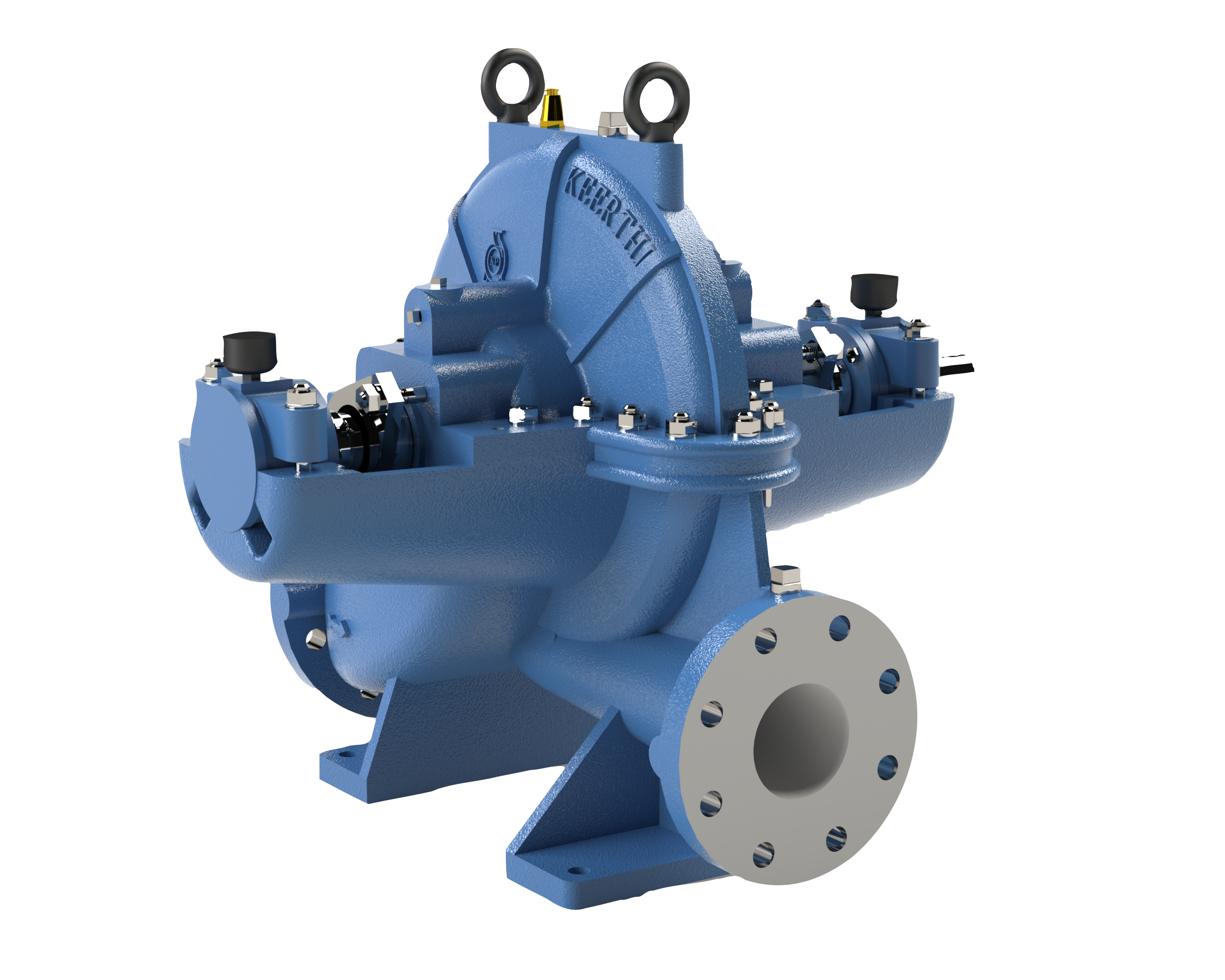

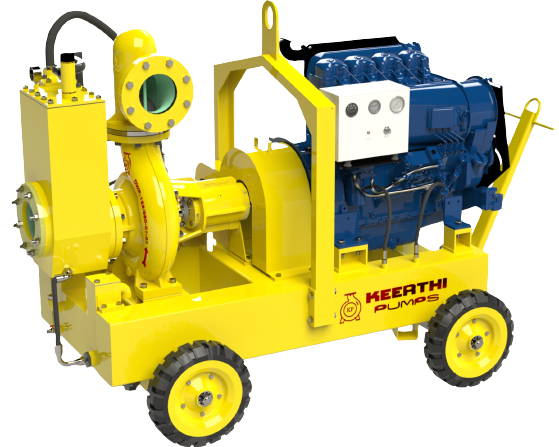

Dewatering Pumps

KEERTHI DWPX -Series Dewatering Pumps designs and develops highly efficient and environment friendly dewatering pumps. KEERTHI PUMPS strive to develop product that best fits customer needs. DWPX De-Watering pumps are specially designed for well point dewatering applications. It can also be used for Mines, Offshore, Building Construction, Marine & Industrial applications to handle muddy/saline water contains solid particles up to 30mm.

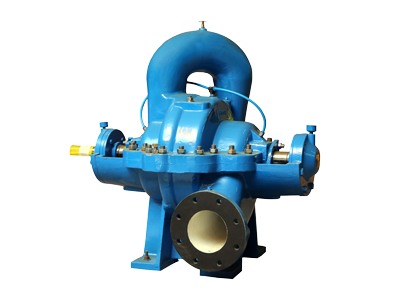

Products

Our product portfolio includes Pulp and paper stock pumps, End suction pumps, Chemical pumps, ANSI chemical process pumps, Axial flow pumps, Mixed flow pumps, Vertical Sump pumps, Horizontal multistage pumps, Firefighting pumps, and De-watering pumps.

Brake Conversion Kit

We want to give you 10% discount for your first order,

Use discount code at checkout

We want to give you 10% discount for your first order,

Use discount code at checkout